How CRM Systems Drive Growth in Manufacturing7 min read

Why do manufacturers need a CRM system?

You might be thinking: how can manufacturers stay competitive in such a fast-changing world? The truth is, today’s manufacturers face mounting pressure from rising customer expectations, global competition, and the accelerating need for digital agility. Profit margins are squeezed, operations are stretched, and the old ways of working simply can’t keep up.

Despite this, many manufacturing businesses are still held back by outdated sales processes, siloed data systems, and limited visibility across departments. It’s a familiar struggle—but one with a modern solution.

A CRM system like Dynamics 365 helps bridge that gap. By centralising customer information, automating workflows, and offering real-time insights, it empowers manufacturers to streamline operations, make smarter decisions, and deliver the kind of service that builds long-term loyalty.

Here are five common challenges faced in manufacturing that a CRM can help solve

Which type of data does a CRM system typically manage?

Sales success hinges on timely, personalised customer interactions. But when sales teams rely on spreadsheets, outdated tools, or disconnected systems, they risk delays, missed opportunities, and internal confusion. If your team can’t quickly access the full picture of a customer’s journey, it’s impossible to act with confidence and the best joined up customer experience.

Why do sales teams struggle without a centralised CRM?

In fast-paced sales environments, sales executives juggling multiple data sources are more likely to miss follow-ups or duplicate work. Without a single source of truth, collaboration suffers and valuable deals can slip through the cracks.

How can a centralised CRM like Dynamics 365 transform your sales?

With a centralised CRM system like Dynamics 365, all customer information—from contact history and order details to live sales opportunities—is available in one place. This gives teams instant access to what they need, when they need it, empowering faster decisions, seamless collaboration, and better customer outcomes. It transforms sales from reactive to proactive.

What are the benefits of operational CRM?

Being able to respond to today’s orders is one thing—but preparing for tomorrow’s demand is where true manufacturing growth and efficiency lies. Yet without clear visibility into sales patterns and customer behaviour, many manufacturers are left guessing. That guesswork can lead to overstocking, underdelivering, and ultimately, missed targets.

Why do manufacturers struggle with demand forecasting?

When sales data lives in separate systems or isn’t tracked at all, forecasting becomes little more than educated guesswork. This increases the risk of holding excess inventory or falling short when demand spikes unexpectedly.

How can CRM systems improve demand forecasting?

A CRM system like Dynamics 365 provides manufacturers with a central view of historical data, sales trends, and customer buying behaviour. It allows teams to build accurate forecasts and align production schedules accordingly. Whether you’re scaling output or refining stock levels, CRM-powered insights help you plan with confidence—minimising waste and maximising revenue potential.

What are the advantages to employees of providing them mobile access to CRM?

Manufacturing no longer happens in just one place. From remote service engineers to global supply chain partners, today’s operations depend on constant connectivity. In this environment, quick access to data isn’t just convenient—it’s critical to keeping production moving and customers happy.

What problem are modern manufacturers facing?

When teams are spread across locations and reliant on on-premise systems, accessing real-time information becomes difficult. This can lead to delays, errors, and miscommunication between departments or partners—especially when time-sensitive decisions are needed.

How does Dynamics 365 keep your team connected and agile?

Dynamics 365 ensures your workforce—whether in the field, on the shop floor, or halfway across the world—can access the tools and information they need from any device. It enables 24/7 visibility into customer data, order status, and service issues, all while maintaining enterprise-grade security. The result? A more connected, agile operation ready to meet demand from anywhere.

How will using a CRM system to create a custom reporting dashboard benefit your team?

Manufacturing moves fast—and leadership decisions need to move even faster. But when reporting relies on spreadsheets and manual processes, managers are left waiting for answers or second-guessing the data they receive. That slows progress and opens the door to costly mistakes.

Why is real-time data important for operational planning?

Traditional reporting methods are time-consuming, often out of date by the time they’re shared, and susceptible to human error. This lack of real-time visibility can hinder operational planning, reduce responsiveness, and limit overall performance.

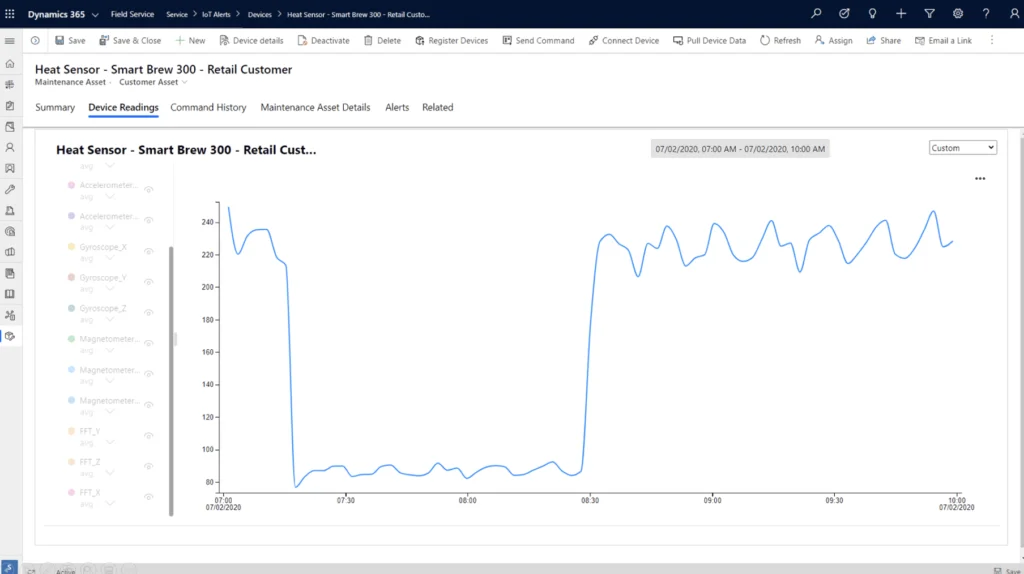

How can Dynamics 365 dashboards improve decision-making?

Dynamics 365 gives managers instant access to real-time dashboards and interactive reports, tailored to track the metrics that matter—whether it’s production output, sales pipeline, or service response times. With clear, reliable insights at their fingertips, leaders can make smarter decisions, spot issues early, and keep performance on track.

What is the role of CRM software in improving customer relationships and retention?

Customer relationships don’t thrive on guesswork. To build trust and loyalty, your teams need to know who they’re talking to, what’s been said, and what matters most to that customer. Without that insight, delivering great service—or securing repeat business—becomes a shot in the dark.

What happens when customer data is incomplete or scattered?

When customer information is scattered or incomplete, sales and service teams struggle to deliver a joined-up experience. Missed follow-ups, repeated questions, or generic interactions can all erode trust and send customers looking elsewhere.

How can Dynamics 365 help your team deliver seamless customer experiences?

Dynamics 365 gives your team a complete view of every customer interaction—from emails and calls to orders and preferences—all in one place. This enables personalised service, consistent communication, and timely follow-up. It’s the foundation for strong, lasting relationships that drive loyalty and repeat revenue.

CRM as a Growth Enabler in Manufacturing

A CRM system isn’t just about managing customer relationships. It connects sales, operations, and service through one scalable platform. When used effectively, it can drive growth across the entire manufacturing value chain.

Key Capabilities That Support Growth

Product Quality and Issue Resolution

CRM tools help identify product defects, track quality metrics, and manage service cases efficiently. By integrating feedback loops and warranty tracking, manufacturers can address issues quickly and improve overall product quality.

Streamline your Quoting Process

Create quotes with ease and consistency to increase conversion of sales opportunities. Leverage templates to shortern lead to close times. Manage and monitor discount levels and track sales productivity.

Business Intelligence and Analytics

Integration with analytics platforms like Power BI enables real-time reporting on production efficiency, sales performance, and customer satisfaction. CRM users can create visual dashboards, uncover trends, and monitor KPIs across departments—helping leadership teams optimise strategy based on data.

Customer-Centric Sales and Service

CRM systems allow manufacturers to personalise customer engagement through automated follow-ups, targeted campaigns, and tailored proposals. With a full view of each customer’s history and preferences, teams can improve conversion rates and drive repeat business.

Benefits of CRM Systems in Manufacturing

A CRM system supports growth in the following ways:

- Improves collaboration with suppliers through shared data visibility

- Empowers employees with up-to-date business intelligence

- Streamlines production order management and capacity planning

- Enhances sales forecasting accuracy

- Supports agile changes to orders and schedules

These outcomes enable manufacturers to respond to market changes quickly, reduce operational waste, and improve profitability.

Adding Intelligence to CRM with AI and Copilot

As manufacturers embrace digital transformation, the next leap forward is the integration of AI into everyday workflows. With Microsoft Copilot built into Dynamics 365, CRM systems are no longer just record-keeping tools—they become intelligent assistants. Copilot helps teams draft emails, summarise customer interactions, suggest next best actions, and generate reports in seconds. AI also enhances forecasting accuracy, highlights emerging sales trends, and spots service issues before they escalate. This added layer of intelligence enables manufacturers to work faster, make smarter decisions, and stay ahead in a highly competitive landscape.

Aligning Systems for Scalable Growth

As manufacturing continues to evolve, success increasingly relies on how well digital systems are integrated with day-to-day operations. A CRM system is key to this shift, helping manufacturers manage complexity, boost efficiency, and deliver stronger results for customers.

For those looking to stay competitive and future-ready, CRM software isn’t a nice-to-have—it’s essential.

Join Our Mailing List

Get the latest Dynamics 365 news, blog updates, webinars events and invitations.